Coating developed creates functional micropatterns

Laser printouts on paper might be used as a platform for low-cost organic electronics, microfluidic, or sensor applications. German scientists at Humboldt University Berlin have now developed a procedure for the selective coating of laser-printed micropatterns on paper. These coatings can be used for further functionalization and enable envisioning various applications in the field of diagnostics and sensors. The study is published in the journal Angewandte Chemie.

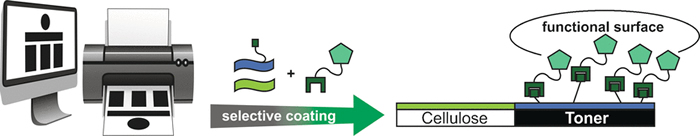

For creating functional micropatterns on paper, a coating must be developed that clearly distinguishes the paper surface from toner.

Using a biochemical selection process, Steffi Große and Patrick Wilke from the group of Hans G. Börner at Humboldt-Universität zu Berlin identified two different peptides, which either adhered to cellulose or toner. These peptides were then used for the coating of the plain paper and the toner pattern, respectively.

Peptides offer a variety of functionalities for the selective covalent attachment of functional moieties. Therefore, to realize further functionalisation with fluorescent proteins, the scientists applied a versatile post-coating functionalization approach.

“We demonstrated the selective coating and the specific functionalization of printed micropatterns with fluorescence microscopy as well as mass spectrometry imaging,” they said. Thus, using simple incubation processes, the scientists transformed an ordinary laser-printed pattern on cellulose paper into a micropattern functionalized with biological molecules.

Such methods are highly valuable for the field of chemical analytics and diagnostics, which is actively turning to disposable, cheap, and handy devices for point-of care diagnostics or sensor applications. Cellulose is a comparably cheap and well defined substance, which is currently seeing a renaissance as a highly versatile material.

Comments are closed, but trackbacks and pingbacks are open.