Stop Scrimping on Circuit Protection: Why Cutting Costs Can Cost You More

As engineers, we are often tasked with cutting costs wherever possible. But in our quest to save every tenth of a cent from the bill of materials, we sometimes make sacrifices in the wrong places. Circuit protection is one of those places where cutting corners can lead to disastrous consequences.

The quality of your designs directly impacts your company’s reputation and, ultimately, your future. Once upon a time, durable goods were truly durable. We could rely on household appliances and vehicles to last for years without fail. But today, many of us spend top dollar on name brands, only to experience costly repairs shortly after purchase. And let’s not even mention extended warranties—often a necessary evil because of these failures.

A significant cause of these failures in modern electronics can be traced back to inadequate circuit protection. Older electromechanical systems are being replaced with advanced embedded systems, but we’re seeing a worrying trend of premature failures due to skimping on the very components designed to protect these systems. The problem? These failures often pass short-term testing, luring engineers into a false sense of security.

Durable vs. Cheap Circuit Protection: A Tale of Two Approaches

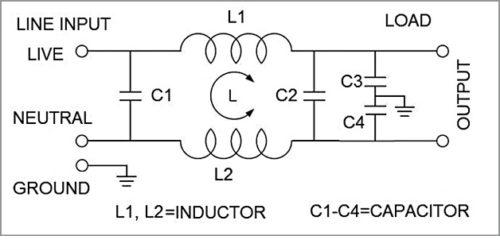

Let’s consider a real-world example: a passive surge suppressor design. This rugged solution involves heavy-duty coils wrapped around ferrite cylinders (Figure 1). These suppressors can handle multiple impulse spikes and surges without breaking a sweat. However, they’re rarely implemented due to space and cost constraints. Instead, many engineers opt for solid-state surge suppressors that meet regulatory standards like UL, FCC, and TUV but are prone to failure in the long run. These components may cost less upfront, but are they really worth the inevitable service calls and controller board replacements?

The truth is that solid-state surge suppressors fail when subjected to prolonged real-world conditions. They may look good on paper and pass short-term testing with flying colors, but when subjected to continuous stress or environmental factors, they falter.

Common Circuit Failures: An Engineer’s Nightmare

If you’ve had to troubleshoot or replace an appliance controller board prematurely, you’ve likely encountered inadequate circuit protection. Many of these issues directly result from poor planning or cost-cutting measures in the circuit protection design. In other words, the very thing that’s supposed to protect your electronics is often the weak link.

The reality is that Metal Oxide Varistors (MOVs) are still widely used because they are inexpensive and perform well during initial testing. But MOVs can only absorb so much energy before they fail, often in a way that leaves the circuit unprotected. Once an MOV fails, it opens up, rendering the protection circuit ineffective and leaving the sensitive components downstream vulnerable to damage.

Effective Circuit Protection Solutions

Despite these risks, several tried-and-true methods effectively protect circuits from faults. For most average use cases, semiconductor Zener diodes or avalanche diodes work well. These components are designed to clamp voltage and protect your circuits from transient voltage spikes.

In stable, non-vibratory environments, gas discharge tubes offer superior clamping capabilities. These ceramic-housed components absorb and dissipate heat, protecting circuits from surges and electromagnetic pulses (EMP). However, over time, ceramics can develop microfractures, allowing contaminants to seep in and gradually reduce the effectiveness of the protection.

Another option to consider is electro-thermal fuses, such as the Polyfuse. These fuses are particularly effective when paired with power supplies that can’t provide enough energy to be hazardous before the fuse activates. These fuses react to excessive current, limiting the damage that can be done to your sensitive electronics.

Crowbar Circuits and Circuit Breakers

Another great option for circuit protection is the crowbar circuit. These circuits react almost instantaneously to dangerous conditions, short-circuiting the power supply to blow a fuse or trip a circuit breaker. This is a far better alternative to allowing the circuit to continue operating and risk destroying an expensive controller board.

And while we’re on the topic of fuses, circuit breakers are an ideal companion to crowbar circuits. They allow users to easily reset the protection mechanism without opening the device and replacing a fuse. This convenience can save both time and money.

Nature’s Power: The Ultimate Test for Circuit Protection

Let’s face it: nature will always have the upper hand. A direct or nearby lightning strike can overwhelm even the most well-protected systems. With the right combination of protection mechanisms, you can do a relatively good job of shielding your equipment from everyday power surges and electrical faults.

As engineers, we can’t control every variable, but we can design for reliability. And that starts with choosing the right circuit protection components.

The Final Word: Don’t Scrimp on Circuit Protection

Cutting corners on circuit protection is a dangerous gamble. MOVs may be cheaper, but they’re far from the best option for long-term durability. When they fail, they do nothing to protect your circuits. Instead, investing in more robust protection solutions, like Zener diodes, gas discharge tubes, Polyfuses, and crowbar circuits, will save you and your customers time and money in the long run.

The next time you’re working on a design, closely examine your protection scheme. Your reputation—and your company’s future—could depend on it.