Please forgive my butchered use of Don Ho’s classic; it is remarkably apt for this new research out of Japan.

Scientists at Yokohama National University have developed a new bubble printing method for creating high-precision liquid metal wiring, a critical development for flexible electronics. This new technique solves challenges in designing bendable and stretchable circuits, paving the way for advancements in wearable sensors and medical implants.

The study, published on Oct. 17 in Nanomaterials, focuses on overcoming the limitations of traditional wiring systems.

“Conventional wiring technologies rely on rigid conductive materials, which are unsuitable for flexible electronics that need to bend and stretch,” said Shoji Maruo, a professor at the Faculty of Engineering at Yokohama National University and corresponding author of the study.

With their flexibility and high conductivity, liquid metals could be a promising alternative. However, these materials face challenges in wiring size, patterning precision, and the electrical resistance caused by their oxide layers.

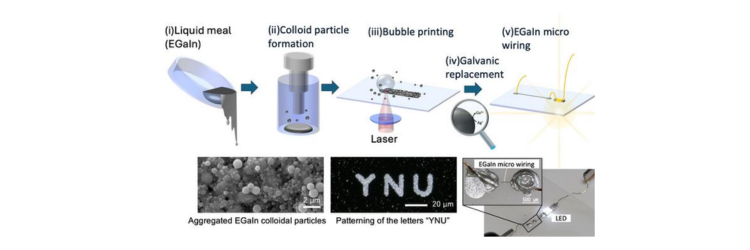

The research team adapted bubble printing—a technique traditionally used for solid particles—to pattern liquid metal colloidal particles of eutectic gallium-indium alloy (EGaIn). Using a femtosecond laser beam, they generated microbubbles that guided EGaIn particles into precise lines on a flexible glass surface.

“The key is to improve conductivity by replacing the resistive gallium oxide layer with conductive silver via galvanic replacement,” Maruo explained.

The result is an ultra-thin, flexible, and highly conductive wiring system. Withh a minimum width of 3.4 μm, the lines achieved a high conductivity of 1.5 × 10⁵ S/m and maintained stable performance even when bent.

The team envisions applying this method to technologies, from wearable sensors to medical devices, where flexibility and precise performance are paramount.