Quantum dot light-emitting diodes are a promising alternative for next-generation display technologies, based on its outstanding electroluminescence properties. With no need for bulky components such as backlight units, QLED displays can be manufactured into an ultrathin form factor.

A joint research team led by KIM Dae-Hyeong (Professor at Seoul National University) and HYEON Taeghwan (Distinguished professor at Seoul National University) from the Center for Nanoparticle Research unveiled a prototype QLED back in 2015. The device had a thickness of only 3 micrometers, one-thirtieth of that of human hair. The ultrathin QLED exhibited outstanding mechanical flexibility, so it can be used in wearable devices, such as electronic tattoos.

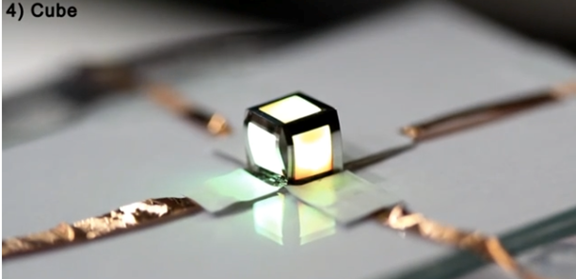

Now the team further advanced this technology and developed a foldable variant of the ultrathin QLED, inspired by origami. The IBS researchers reported three-dimensional foldable QLEDs that can be freely transformed into various user-customized 3D structures, such as butterflies, airplanes, and pyramids. Given the popularity of foldable smartphones, the advancement of foldable display technology may provide opportunities for next-generation electronics with user-customized form factors with complex structures.

Foldability is a result of a new fabrication process that can partially etch the epoxy film deposited on the QLED surface without damaging the underlying QLED. Using a power-controllable carbon dioxide pulsed laser and the silver-aluminum alloy-based etch-stop layers, the etching depth can be precisely controlled. Researchers, for example, were able to precisely control the radius of curvature down to less than 50 micrometers. Under such a small curvature radius, the fold line resembles a sharp edge with no visible curvature.

The entire QLED including the crease region was able to maintain a stable light-emitting performance even when after it was repeatedly folded 500 times

Original Release: Eureka Alert