Understanding Friction at the Atomic Level

Friction is an unavoidable enemy and a major source of service failure. It can reduce the lifespan of any machinery, from bicycles and cars to airplanes and assembly lines.

University of Pittsburgh’s research unveils the atomic-scale friction of a single tungsten asperity, or rough edge, in real-time, showing atomic motion for the first time with electron microscopy. They recently published their work in the journal Nature Nanotechnology.

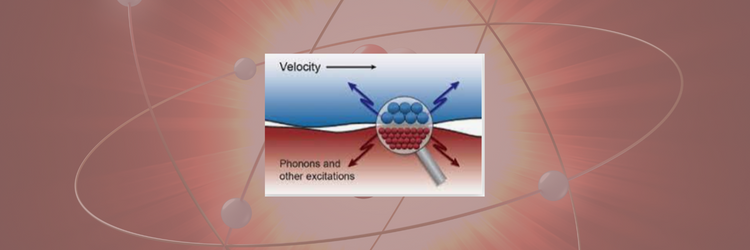

Researchers in the study could see the sliding pathway of interface atoms and the dynamic strain and stress evolution on the interface, previously only shown by simulations. They viewed the movement of atoms across the surface when two surfaces made contact and moved.

Although this study focused on tungsten atoms, the method can be applied to any material to understand friction and wear. No matter how smooth and clean the surface is, friction still occurs at the atomic level. This knowledge can lead to better lubricants and materials to minimize friction and wear as much as possible, extending the life of mechanical systems.

The published paper is “Atomic-scale friction between single-asperity contacts unveiled through in situ transmission electron microscopy.”