What Do You Get When You Heat Gallium Nitride and Magnesium?

Researchers at Nagoya University found that a simple thermal reaction of gallium nitride (GaN) with metallic magnesium (Mg) results in a distinctive superlattice structure. A first, the research team identified the insertion of 2D metal layers into a bulk semiconductor. Observing the materials through a variety of characterization techniques, they uncovered new insights into the process of semiconductor doping and elastic strain engineering. Their findings are published in the journal Nature.

GaN is poised to replace traditional silicon semiconductors in applications requiring higher power density and faster operating frequencies. This includes LEDs, laser diodes, and power electronics—including critical components in electric vehicles and fast chargers.

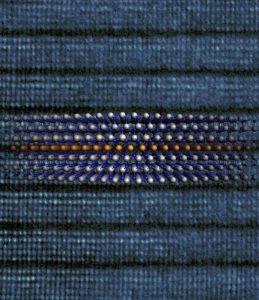

Semiconductors acquire p-type or n-type conductivity through doping, intentionally introducing specific impurities into a pure semiconductor material to significantly alter its electrical and optical properties. For GaN semiconductors, Mg is the only known element to create p-type conductivity until now. To improve the conductivity of p-type GaN, Jia Wang and his colleagues conducted an experiment in which they patterned deposited metallic Mg thin films on GaN wafers and heated them up at a high temperature, known as annealing. They then observed the spontaneous formation of a superlattice featuring alternating layers of GaN and Mg.

CREDIT: Jia Wang

“Although GaN is a wide-bandgap semiconductor with mixed ionic and covalent bonding, and Mg is a metal featuring metallic bonding, these two dissimilar materials have the same crystal structure, and it is a strikingly natural coincidence that the lattice difference between hexagonal GaN and hexagonal Mg is negligibly small,” Wang said. “We think that the perfect lattice match between GaN and Mg greatly reduces the energy needed to create the structure, playing a critical role in the spontaneous formation of such a superlattice.”

The intercalation behavior, which they named interstitial intercalation, leads to compressive strain to the host material. They found that the GaN being inserted with Mg layers sustains a high stress of more than 20 GPa, equivalent to 200,000 times atmospheric pressure, making it the highest compressive strain ever recorded in a thin-film material.