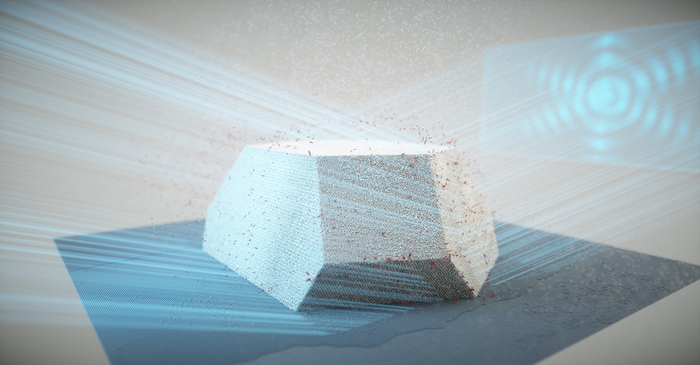

What does one catalyst nanoparticle at work look like?

A DESY NanoLab research team observed a single catalyst nanoparticle at work—and rendered a 3D look. The experiment demonstrated how the chemical composition of the nanoparticle’s surface becomes more active under reaction conditions and allows a better understanding of industrial catalytic materials. Research findings are published in the journal Science Advances.

The team developed a technique for labelling individual nanoparticles and identifying them in a sample. According to Thomas Keller from DESY NanoLab and in charge of the project, “The diameter of the labelled particle is around 100 nanometers, and it is similar to the particles used in a car’s catalytic converter.”

The team also measured the mechanical strain within its surface. By comparing the observed and computed facet-dependent strain, conclusions can be drawn concerning the chemical composition at the particle surface. The chemical composition of the surface, and the shape and size of the particles have a significant effect on their function and efficiency. The X-rays allow researchers to detect changes of as little as 0.1 in a thousand in the strain, which in this experiment corresponds to a precision of about 0.0003 nanometers (0.3 picometres).

It’s the first time that the details of the structural changes in such catalyst nanoparticles while in operation can be observed. It is a major step forward in understanding an entire class of reactions that make use of alloy nanoparticles.

Original Release: Eureka Alert