Why Some Foams Collapse, and Some Don’t

Researchers from Tokyo Metropolitan University are demonstrating how liquid foams collapse by observing individual collapse “events” with high-speed video microscopy. Cracks in films led to a receding liquid front that sweeps up the original film border, inverts its shape, and releases a droplet that hits and breaks other films. Their observations and physical model are providing important insights into how to make foams more or less resistant to collapse.

The collapse of foams is a challenging problem. A team led by Prof. Rei Kurita of Tokyo Metropolitan University is experimenting on generating liquid foams sandwiched between two thin, transparent plates, providing direct access to the whole range of complex collapse phenomena. Until now, it was not known how droplets were formed and why sometimes they weren’t.

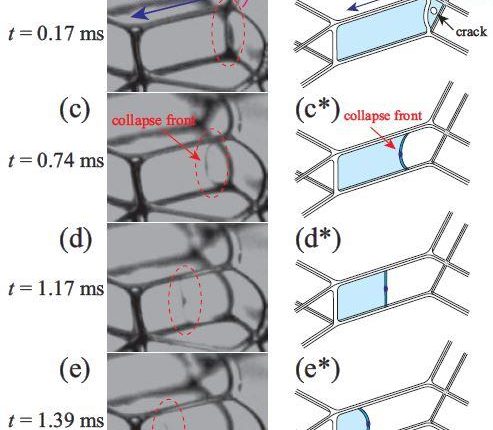

The researchers are making progress. When an initial crack forms in a film, the film recedes and leaves a wobbling line of liquid where the original film border was. this is called the Released Vertical Plateau Border (RVPB).

Wobbling causes an accumulation of liquid in the center of the RVPB. When a further crack is created in the remaining film, a receding line of liquid is created which sweeps up the RVPB. This front has a tendency to invert in shape as it travels due to an inertial effect. This inversion causes a droplet to be released, initiating a cascade of film breakage events.

The team replaced lab reagents with detergent, creating a much more long-lasting foam. When a bubble bursts at the side, there is a similar accumulation of liquid in the center of RVPBs. The group’s insights are vital for guiding the design of new foam materials with enhanced properties.